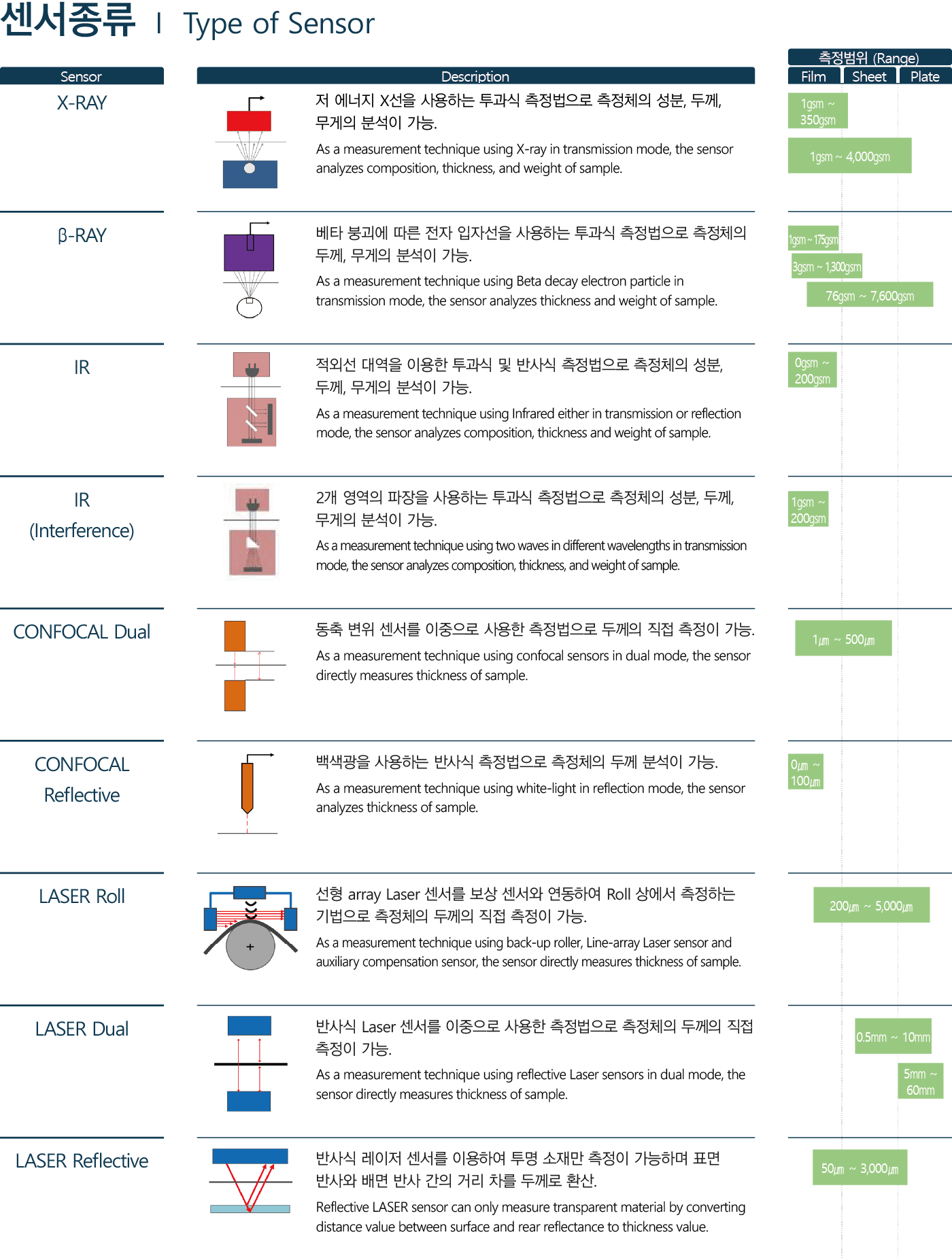

1050H Thickness Gauge

본문

페이지 정보

1050H Thickness Gauge

■ One-size-fits-all Type

3-piece integrated gauge

- Thickness, Weight Measurement (Thickness, Weight, Density Simultaneous Analysis)

- + Integrate automation with contact thickness gauge

The whole process of cathode, anode, coating, and press used in the production of secondary batteries can be integrated into one measuring instrument.

3-piece integrated gauge

- Thickness, Weight Measurement (Thickness, Weight, Density Simultaneous Analysis)

- + Integrate automation with contact thickness gauge

The whole process of cathode, anode, coating, and press used in the production of secondary batteries can be integrated into one measuring instrument.

SPECIFICATIONS

| Description | |

|---|---|

| Application | For secondary battery electrode plate manufacturing process, coating,Roll Press |

| range | 0.03mm~3.6mm |

| width | max. 1,000mm(C-Frame), max.2,000mm(O-frame) |

| Pitch | 1mm (0.5-10mm) |

| Spot size | 70µm/300µm |

| Operating temperature | Up to 45℃(60℃) |

| Option 1 | Thickness, Weight, Integral cathode Con+β-ray anode Con+X-ray (Simultaneous analysis of thickness, weight and density) |

| Option 2 | Option 1 + Touch Type Automatic Measurement Gauge Resolution: 0.1µm |

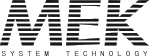

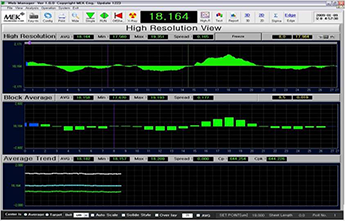

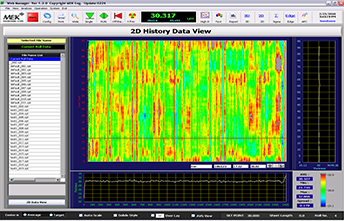

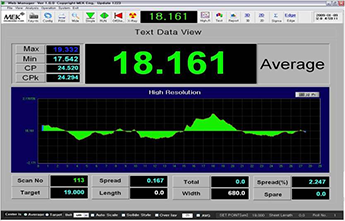

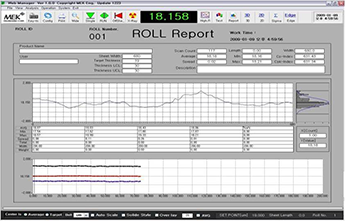

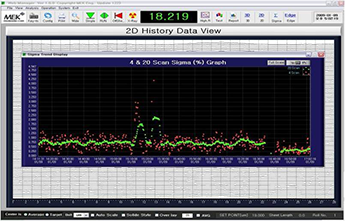

PROGRAM SOFTWARE

MEK 프로그램의 특징

• 사용자 친화적 구성 - 직관적 인터페이스

• 사용자 친화적 구성 - 직관적 인터페이스 • 언어 선택가능 한, 영, 중, 일

• 언어 선택가능 한, 영, 중, 일 • User HMI와 측정 데이터 통신(선택사양)

• User HMI와 측정 데이터 통신(선택사양) • 사용자 요청에 맞춤 제작 가능

• 사용자 요청에 맞춤 제작 가능

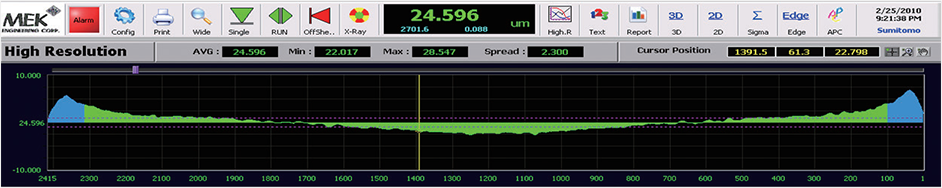

기본 화면

| Description | |

|---|---|

| Run Environment | Labview 기반 자체 제작 소프트웨어 |

| Data display | gsm (basis weight) / um (thickness) Spatial resolution : 1mm |

| Data compatibility | Microsoft Excel, CSV |

| Functions | Full automatic edge detection Full mapping of entire LOT (2D & 3D reconstruction) Real-time Profile & SPC (Staitstical-Process-Control) Trend chart FFT (Fast-Fourier-Transform) Analysis of MD Profile LOT Statistics & History 4 & 20 Scan Sigma |

| Language | English, Korean, Chinese, Japanese (Hungarian translation available upon request) |

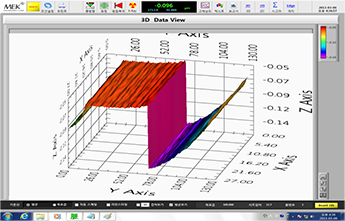

APC(Automatic Profile Control)

MEK 프로그램의 특징

- • 최적화된 두께 제어 알고리즘

- • 신속한 두께 제어

- • Auto Mapping: 센터볼트 기준

- • 매끈한 Mill Roll 외관

- • 수 Micron이내의 Control Gain 자동 조정

- • 다이볼트 온도 피드백 제어 (선택사양)

- • MD (Machine Direction) 제어 가능 (선택사양)

APC적용 후 프로파일 변화

Before

APC control begins after the target thickness is changed to 60㎛ to 30㎛

After 5min

Regulates Control Gain of auto-die, reducing variation in thickness

After 10min

Steadily analyzes and controls the thickness profiles

After 15min

Within 15min, produces the best result