1050H Thickness Gauge

본문

페이지 정보

1050H Thickness Gauge

■ One-size-fits-all Type

3-piece integrated gauge

- Thickness, Weight Measurement (Thickness, Weight, Density Simultaneous Analysis)

- + Integrate automation with contact thickness gauge

The whole process of cathode, anode, coating, and press used in the production of secondary batteries can be integrated into one measuring instrument.

3-piece integrated gauge

- Thickness, Weight Measurement (Thickness, Weight, Density Simultaneous Analysis)

- + Integrate automation with contact thickness gauge

The whole process of cathode, anode, coating, and press used in the production of secondary batteries can be integrated into one measuring instrument.

SPECIFICATIONS

| Description | |

|---|---|

| Application | For secondary battery electrode plate manufacturing process, coating,Roll Press |

| range | 0.03mm~3.6mm |

| width | max. 1,000mm(C-Frame), max.2,000mm(O-frame) |

| Pitch | 1mm (0.5-10mm) |

| Spot size | 70µm/300µm |

| Operating temperature | Up to 45℃(60℃) |

| Option 1 | Thickness, Weight, Integral cathode Con+β-ray anode Con+X-ray (Simultaneous analysis of thickness, weight and density) |

| Option 2 | Option 1 + Touch Type Automatic Measurement Gauge Resolution: 0.1µm |

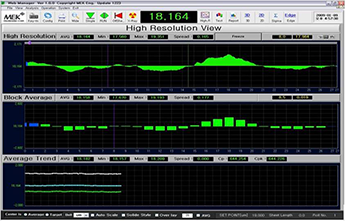

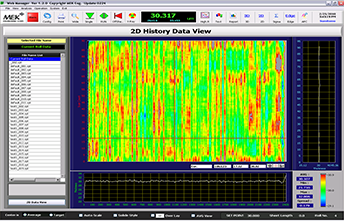

PROGRAM SOFTWARE

MEK程序的特点

• 用户友好型配置 - 直观界面

• 用户友好型配置 - 直观界面 • 可选择语言 - 韩语,英语,中文,日语

• 可选择语言 - 韩语,英语,中文,日语 • 用户HMI和测量数据通信(选配)

• 用户HMI和测量数据通信(选配) • 可根据用户要求定制

• 可根据用户要求定制

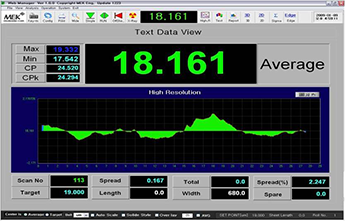

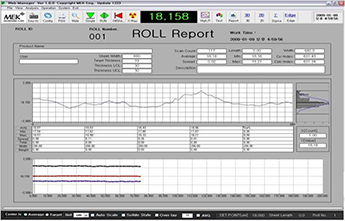

基本界面

| Description | |

|---|---|

| Run Environment | LabVIEW-based proprietary software |

| Data display | gsm (basis weight) / um (thickness) Spatial resolution : 1mm |

| Data compatibility | Microsoft Excel, CSV |

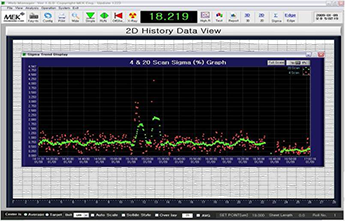

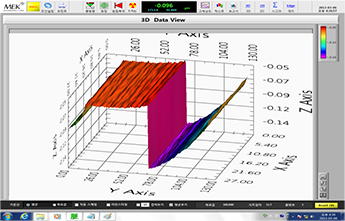

| Functions | Full automatic edge detection Full mapping of entire LOT (2D & 3D reconstruction) Real-time Profile & SPC (Staitstical-Process-Control) Trend chart FFT (Fast-Fourier-Transform) Analysis of MD Profile LOT Statistics & History 4 & 20 Scan Sigma |

| Language | English, Korean, Chinese, Japanese (Hungarian translation available upon request) |

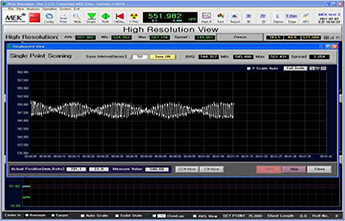

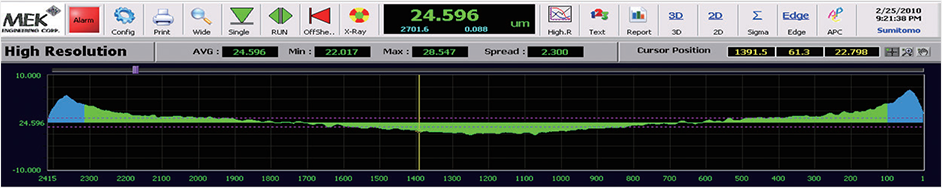

APC(Automatic Profile Control)

MEK程序的特点

- • 优化的厚度控制算法

- • 快速厚度控制

- • Auto Mapping: 中心螺栓标准

- • 光滑的轧辊外观

- • 自动调整控制增益在数微米内

- • 模具螺栓温度反馈控制(可选)

- • MD (Machine Direction) 控制选项(可选)

应用APC后的配置变化

Before

APC control begins after the target thickness is changed to 60㎛ to 30㎛

After 5min

Regulates Control Gain of auto-die, reducing variation in thickness

After 10min

Steadily analyzes and controls the thickness profiles

After 15min

Within 15min, produces the best result